Deep inside Madagascar’s humid forests, researchers stumbled upon something that felt almost impossible: a spider web stretched across an entire river channel. At first glance, it looked like sunlight reflecting on water, but closer inspection revealed a biological engineering marvel.

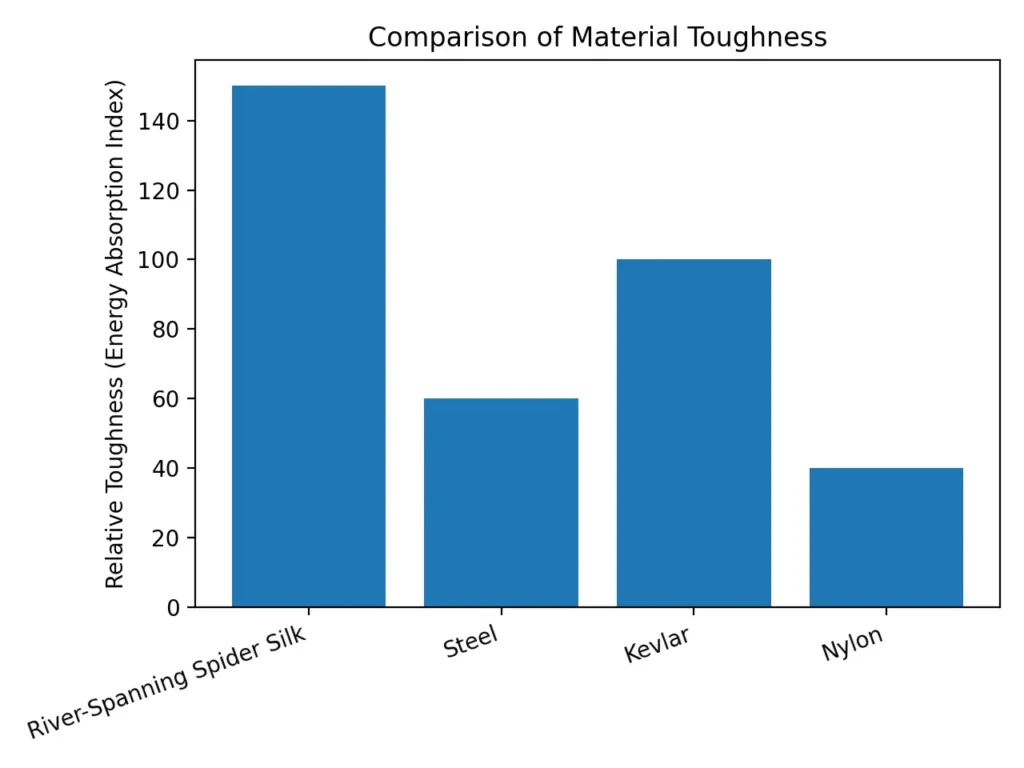

The river-spanning spider silk holding the web wasn’t ordinary thread. It resisted strong wind, survived rain, and even absorbed the impact of flying insects traveling at surprising speed. Scientists later confirmed the truth river-spanning spider silk is one of the toughest natural fibers ever studied. What makes this discovery fascinating is not just strength, but performance. Unlike rigid materials that snap under sudden force, this silk stretches and returns to its shape. Researchers now see it as a blueprint for next-generation fibers, from medical sutures to protective gear. In a world searching for lighter and more sustainable materials, a small spider may quietly be pointing engineers toward the future.

The river-spanning spider silk produced by Caerostris darwini has become a major subject of biomaterials research. Scientists study it because it combines flexibility, elasticity, and tensile durability better than many synthetic fibers currently in use. The spider builds massive webs suspended above flowing water, where few predators and competing spiders exist. To survive in that environment, the silk must endure constant tension from wind, moisture, and gravity. Laboratory tests show the fiber can absorb extraordinary amounts of energy before breaking. That quality is known as toughness, and it is exactly why researchers are interested. Unlike many human-made fibers that are strong but brittle, this silk bends, stretches, and recovers. Understanding how the spider produces river-spanning spider silk could eventually help scientists design sustainable materials for industries ranging from medicine to aerospace.

Table of Contents

River-Spanning Spider Produces Silk Tougher Than Steel

| Key Feature | Details |

|---|---|

| Spider Species | Caerostris darwini |

| Habitat | Madagascar rainforests near rivers |

| Web Span | Up to 20–25 meters |

| Material Property | Extremely tough and elastic |

| Comparison | Tougher by energy absorption than many steel alloys |

| Function | Captures large flying insects above water |

| Scientific Interest | Biomaterials, medicine, aerospace engineering |

| Unique Behavior | Spins webs across open rivers |

The Darwin’s bark spider demonstrates that advanced material science is not limited to laboratories. Its river-spanning spider silk shows how strength and flexibility can coexist in a single fiber. By building webs across rivers, the spider occupies an ecological niche no other spider regularly uses. Researchers now view this silk as a guide for future manufacturing. If scientists successfully reproduce it, industries from healthcare to aerospace could benefit. Medical sutures may become safer, protective gear lighter, and engineering structures more efficient. Sometimes innovation does not begin with machines or factories. Sometimes it begins with careful observation of the natural world. Hanging quietly above a flowing river, a spider may be offering a lesson in design that engineers are only beginning to understand.

Discovery In Madagascar’s River Systems

- The discovery began during biodiversity surveys in Madagascar’s rainforests. Researchers noticed giant orb webs suspended over moving water, something rarely seen in spider behavior. At first, scientists thought the strands were accidental, perhaps blown across by wind. After repeated observations, it became clear the spider deliberately selected rivers as building sites.

- Rivers are natural insect corridors. Many species of flying insects hatch near water and follow the airflow along river channels. For a predator, this location offers a constant supply of prey. However, it also creates engineering challenges. A web stretched across open space experiences wind stress and vibration. Ordinary silk would snap quickly. The river-spanning spider silk evolved specifically to survive those conditions.

Why The Silk Is Tougher Than Steel

- When people hear the phrase “tougher than steel,” it often causes confusion. Steel is extremely strong, but toughness measures something different. Strength describes how much force a material can handle before breaking. Toughness measures how much energy it can absorb before failure.

- Steel resists pulling forces well, but sudden impacts can cause cracks or deformation. The spider silk behaves differently. When a fast-moving insect hits the web, the strands stretch dramatically instead of snapping. The energy spreads across the entire web.

- Scientists testing river-spanning spider silk observed that it can extend several times its original length before breaking. After the impact, it often returns to its original shape. That combination of elasticity and durability makes the material remarkable. It is not just strong; it is resilient.

A Strategy Built Around Rivers

- Most spiders avoid exposed locations because wind damages their webs and predators can easily reach them. This species takes the opposite approach. The river environment actually benefits it.

- Above water, there are fewer rival spiders. Predators such as ants have difficulty reaching the web. At the same time, insects concentrate over the river, especially during evening hatching periods. The spider gains a steady food supply.

- The river-spanning spider silk allows the web to hang freely in mid-air, acting like a suspended net. Large insects such as mayflies and dragonflies collide with the web at speed. Without such tough silk, the spider would lose its trap after the first impact.

How The Spider Builds A Giant Web

- The web construction process is surprisingly clever. The spider climbs to a high branch on the riverbank and releases a fine strand of silk into the air. Wind currents carry the thread across the river. Eventually, it catches on vegetation on the opposite side.

- Once the first line attaches, the spider reinforces it repeatedly, turning a thin thread into a strong bridge cable. Only after securing the bridge line does it begin weaving the circular web below.

- Some bridge lines span more than 20 meters. The spider’s entire hunting strategy depends on the reliability of river-spanning spider silk. If the first line fails, the spider risks falling into the water or losing valuable energy.

What Makes The Silk Special At The Molecular Level

- Under microscopic examination, researchers found the silk is made from complex protein chains arranged in repeating patterns. The structure contains two important regions. The first consists of tightly packed crystalline protein segments. These provide strength and prevent tearing. The second contains flexible protein sections that stretch under force. Together, they form a natural composite material.

- The spider produces the fiber as a liquid protein solution inside its body. As the silk passes through its spinnerets, changes in pressure and acidity transform the liquid into a solid thread. This transformation happens instantly and without heat or chemicals.

- Human manufacturing typically requires high temperatures, solvents, and mechanical processing to create similar fibers. The spider achieves it at room temperature using water-based proteins, making river-spanning spider silk a model of efficient production.

Potential Uses in Human Technology

Scientists hope to recreate artificial spider silk because harvesting from real spiders is not practical. Spiders are territorial and often attack each other, making large-scale farming impossible. If researchers successfully reproduce river-spanning spider silk, the applications could be extensive. In medicine, the material could be used for biodegradable stitches that move naturally with the body. It may also help repair ligaments or support tissue regeneration. Unlike synthetic sutures, silk-based fibers would gradually dissolve after healing. In protective equipment, lightweight armor made from flexible fibers could improve comfort and mobility. Helmets and safety clothing could better absorb impacts. In engineering, the material’s strength-to-weight ratio could benefit aerospace design. Parachute lines, drone components, and delicate suspension cables could become lighter and more durable.

Challenges In Replicating the Silk

Producing the silk protein itself is not the main obstacle. Scientists have already engineered bacteria and yeast to create similar proteins. The challenge lies in spinning the fibers. Inside the spider, the spinning process carefully aligns molecules as the silk forms. Pressure, pH balance, and mechanical forces interact simultaneously. Replicating that biological precision in factories remains difficult. Current artificial fibers approach the strength of natural silk but still fall short of the performance seen in river-spanning spider silk. Researchers now believe the spinning technique is just as important as the protein composition.

Why This Discovery Matters

Modern industries seek materials that are lighter, stronger, and environmentally responsible. Metals are heavy, plastics create pollution, and advanced composites require energy-intensive production. The spider’s silk offers a different path. It is biodegradable, renewable, and highly efficient to produce. Engineers increasingly study biological systems for inspiration, a field known as biomimicry. Nature often develops solutions through gradual adaptation. In this case, a spider evolved a fiber capable of supporting large webs over open water while capturing fast prey. By studying this system, scientists hope to design materials that combine performance with sustainability. The discovery also changes how researchers think about small organisms. Even tiny creatures can solve complex engineering problems. The spider does not simply spin a web; it manufactures a high-performance material using a natural process.

FAQs on River-Spanning Spider Produces Silk Tougher Than Steel

What Is River-Spanning Spider Silk?

It is a unique biological fiber produced by the Darwin’s bark spider that allows it to build massive webs across rivers. The material is known for its elasticity and durability.

Is Spider Silk Really Tougher Than Steel?

Steel is stronger in pure tensile force, but spider silk absorbs more energy before breaking. In terms of toughness, the silk outperforms many steel materials.

Where Does This Spider Live?

The species lives in Madagascar, mainly near forest rivers and streams where insects gather.

Can Scientists Manufacture It Artificially?

Researchers are trying to produce synthetic versions using engineered microorganisms, but copying the natural spinning process remains challenging.